How Much Do You Know About Cashew Processing?

The cashew is a hard nut to crack, quite literally. To understand how you get to the ivory cashew kernel that you enjoy, it is important to know about cashew processing - where it comes from and what it goes through to reach its edible stage. Cashew is a tropical shrub that is found in countries like India, Brazil, Vietnam, Indonesia, Ivory Coast, Benin, Ghana and more such tropical countries. The origin or source of the cashew also plays a role in cashew processing as the raw nut sizes can vary from region to region. The origin also affects characteristics of the cashew kernels, such as size, taste, texture and colour. Indian-origin cashew nuts are sought after world over due to its mildly sweet, buttery, creamy taste and texture.

Of Apples And Seeds: How Is The Cashew Formed?

The cashew tree is a seasonal tree that yields fruit once a year. During the season, the tree first starts to flower and then forms the drupe or the cashew seed. What is referred to as the cashew apple, starts to form around it. As harvest season approaches, the fleshy fruit forms fully. The yellow and red cashew apple is an accessory or pseudo fruit - the true fruit of the tree is the kidney-shaped grey-ish seed protruding from the fruit, inside which we find the cashew kernel. Raw cashew nuts are harvested when the apple falls off the tree - this ensures the seed is fully matured.

Cashews Are A Heavily Protected Nut

So, why exactly is the cashew a hard nut to crack? This is because the raw cashew nut, which is found sticking out of the cashew apple, has a hard outer shell and several layers of protection. Not only is it difficult to crack open but it also contains anacardic acid, an allergenic resin which is known to cause skin irritation. There are certain techniques applied during cashew processing to open the nut so as to protect the individual cracking them open [when done manually] and also to protect the kernel within.

Once shelled, the cashew is found covered in a pinkish-brown skin or peel called testa [also referred to as the cashew husk]. This is yet another layer of protection that surrounds the kernel. To remove this testa requires either machines or a combination of machines and manual labour. The testa that does not get removed from machines alone, is removed by hand by skilled labour using short knives.

This was a brief introduction into the nature of the cashew nut. The entire cashew process is far more elaborate. Below we want to provide a brief overview of the cashew processing stages by Achal.

The Various Stages Of Cashew Processing And Manufacture

Procurement

The cashew processing business begins from the procurement stage. Due to the seasonal nature of cashew, this is actually a rather important step for any manufacturer. The cashew season differs from region to region. In India, the season is from March to May. Other countries have varying seasons. Since AchalOrg’s certified organic cashews are 100% Indian, we have to procure the raw cashew nuts during the season of March to May and store them for processing for the entire year.

The farmers bring their daily harvest to a collection centre in their area [we have designated collection centres in Goa and Maharashtra regions near our project areas]. Their organic raw cashew nut produce is weighed, tagged and stored. It is then transported to our manufacturing units for the next stage of cashew processing.

Drying

Raw cashew nuts need to be dried before they can be processed further. Drying is actually an important step that can determine the outcome of the cashew kernel. It has to be completed in the weeks following harvest and then stored. Depending on the volume of raw nuts required for processing throughout the year, it is a labour-intensive process requiring large yards, manual labour and a good amount of sunlight. Unseasonal rains can affect this process.

Roasting

There are several methods to help crack open the hard outer shell of the raw cashew nut such as drum roasting or using a rotary cylinder. A few decades ago, Achal innovated its own method of roasting, and this plays a huge role in the quality of the final output of cashew kernels. We use a steam roasting technique which was the fourth major innovation in cashew processing and is now adopted by several other manufacturers. Due to our having over 40 years of experience in the cashew industry, there are several techniques and innovations implemented by Achal over the years that revolutionised the cashew manufacturing industry and gave Achal its reputation for processing the best quality of cashew kernels.

Shelling

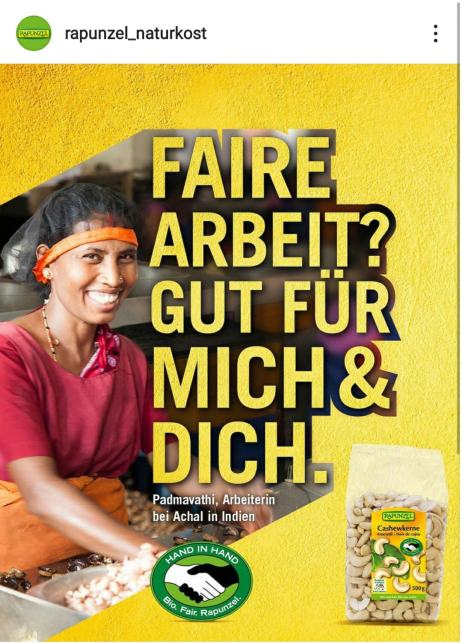

The roasted raw cashew nuts then move to the shelling department as the next stage in cashew processing. Here, machines are used to crack open the outer shell and scoop out the kernel. It requires skilled labour to ensure no damage comes to the kernel. This stage of cashew processing in India has come under a negative light due to the effect of the earlier mentioned anacardic acid coming into contact with workers’ hands. However, at Achal, the workers follow certain protocols to ensure there is no negative impact on their hands from the shell liquid. In fact, one of our happy shellers was featured on the marketing campaign of our customer in Germany. We celebrate 25 years of organic and fair trade practices with them, this year in 2021.

Peeling

After the raw cashew nuts are shelled, we find the testa-covered kernel within - the cashew kernel in this stage is referred to as ‘natural wholes’ or NW. In India, roasted natural wholes are a delicacy as well. The roasted NW will have brittle testa which can be easily peeled by hand before consuming the kernel. However, most cashew nuts normally move from this stage to the next, which is peeling. There are several steps involved in the peeling process of cashews to ensure the nuts are completely free of the testa without breaking the cashew kernels. Whole cashew kernels are the most sought after, hence, care must be taken to ensure less breakage and resulting pieces as possible. Cashew pieces are also utilised in multiple ways, mainly as ingredients in India. The testa or husk is also a byproduct that has industrial uses.

Grading

Once cashew nuts are peeled, they are edible. However, this is where the cashew process gets more interesting. Based on several characteristics of the cashew, they are sorted into different grades. Whole cashews are separated from broken cashew pieces. The pieces and whole cashews are then graded separately.

Whole cashew nuts are graded based on characteristics like size, finish, and colour. Due to the unique kidney shape of the cashew nut, the size grading is done by count. Counts basically indicate the number of cashew nuts per pound. The highest grade available is the 150 count. Our XXXL cashew nuts are of the 150 size and count. This grade is rare and quite prized. To get an understanding of its rarity - for every 100kg of produced kernels you only get between 0.08 - 0.11% of 150. Grab this limited edition product on our site :)

The other grades are 180 (our XXL), 210 (our XL), 240 (our L) and 320 (our M). These are the most commonly sought after grades but the highest availability in the market is in the range of 240s and 320s. So for those who like larger kernels, please shop for our XXXL - XL range. There are also smaller counts of 380, 400 etc as well as grades that are differentiated based on characteristics like colour, watermarks and spots which are inevitable as the cashew is a natural product.

Pieces are also graded separately based on the size of the pieces. Cashews naturally broken into two down the middle are called splits or halves. Then it gets further graded based on the number of pieces a whole cashew has broken into all the way up to tiny bits and powder.

The pricing of cashews is based on their grades. The best looking, biggest kernels which are rare are naturally priced the highest. Due to cashew being a fluctuating commodity, prices can vary constantly based on market conditions.

Inspection

Since the cashew is a food product and a natural product, it needs to be stored properly. Before the graded cashew nuts are packed and stored, they go through several kill steps to ensure there is no risk of microbial infestations. They are also inspected for foreign matters. After a thorough inspection, they are packed and stored.

Storage and Packing

The final stage of cashew processing is packing and storage. Cashew nuts at Achal are packed in vacuumised, nitrogen flushed poly pouches. This keeps the cashews fresh and free from any risk of infestation.

And That’s How You Get Your Cashews!

It takes between 6 to 10 days for the cashew nut to go through this entire cycle till the cashew is ready for packing and dispatch. This is why cashew production takes place in planned cycles. Cashews have a good shelf life of up to 9 months. At Achal, a year’s crop is exhausted before the next crop cycle begins ensuring the best quality Indian cashews all year round. This article only provides an overview of the production cycle, the cashew process is elaborate with multiple small steps within these larger processes. We hope you have got a glimpse of how your cashews are processed.

For those interested in the workings of a cashew factory and the processes involved, our cashew factory is open for visitors [subject to Covid-19 situation]. Do let us know if you would like a tour and learn more about how a cashew factory operates.

Add a comment

Type in your comments. The required fields are marked *. Your email address will not be published.